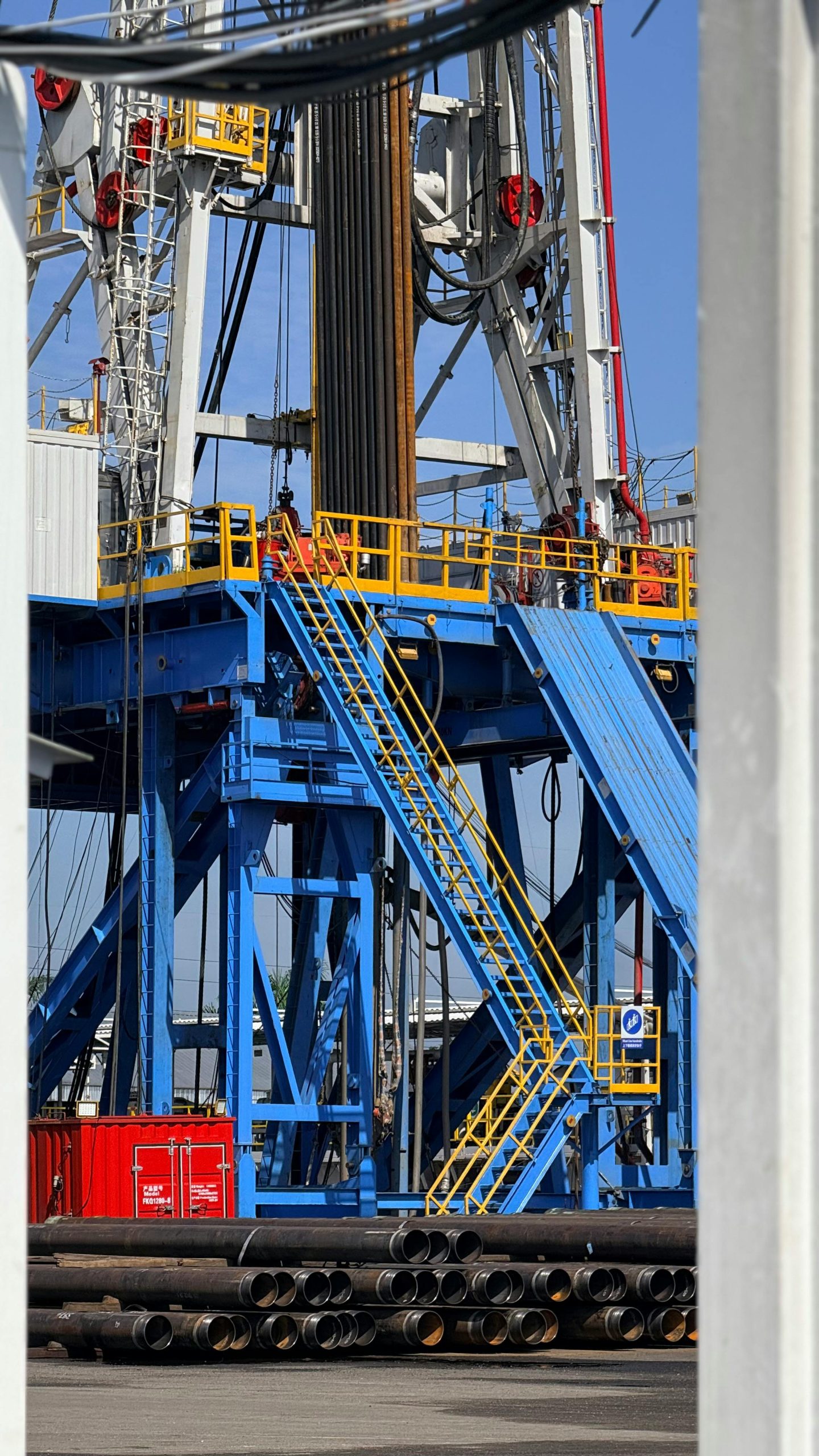

Modern oil pipeline construction faces unprecedented challenges in unstable soil conditions and complex terrain. Micropile technology has emerged as a game-changing solution, offering superior load-bearing capacity and enhanced stability for critical infrastructure projects. According to recent industry data from 2026, micropile foundations reduce installation time by up to 40% compared to traditional methods while providing exceptional corrosion resistance in harsh environments.

Understanding micropile foundation technology

Micropile foundations represent a sophisticated engineering solution that combines steel reinforcement with high-strength grout to create deep foundation systems. These slender structural elements typically range from 100 to 300 millimeters in diameter, extending deep into stable soil layers or bedrock to transfer structural loads effectively.

Also read : Strategies for uk businesses to innovate and lead their industry

The construction process involves drilling precise boreholes to predetermined depths, then installing steel reinforcing elements such as threaded bars, steel pipes, or H-sections. High-pressure grout injection follows, creating a composite structural system that bonds the steel reinforcement with surrounding soil or rock formations through both friction and end-bearing mechanisms.

In oil and gas applications, micropiles excel due to their ability to handle both compression and tension loads while resisting lateral forces from pipeline movement and thermal expansion. The corrosion-resistant materials and protective coatings used in these systems ensure long-term structural integrity in harsh industrial environments. Their minimal installation footprint makes them particularly valuable in congested pipeline corridors where space constraints limit conventional foundation options.

Also to discover : Essential guide to construction mats for builders and developers

How can your next pipeline project benefit from this advanced foundation technology? When engineering teams opt for the reliable micropile oil pipeline tube from vallourec, they gain access to proven solutions that deliver both structural integrity and long-term durability in the most demanding conditions.

Why these advanced systems revolutionize pipeline infrastructure

Micropile systems deliver unmatched stability that transforms how oil and gas infrastructure handles complex ground conditions. Unlike conventional foundation methods, these advanced systems create deep-seated anchoring points that remain stable even when soil layers shift or settle over time.

The technology excels in challenging terrain where traditional foundations fail. Soft clay, expansive soils, and areas with varying subsurface conditions no longer pose insurmountable obstacles. Micropile systems adapt to these difficult environments by transferring loads through unstable layers directly to competent bearing strata.

Dynamic loading from pipeline operations, thermal expansion, and equipment vibrations requires exceptional resistance. These systems absorb and distribute dynamic forces efficiently, preventing structural fatigue that typically compromises pipeline integrity over decades of operation.

Environmental extremes in oil and gas projects demand superior durability. Micropile infrastructure withstands temperature fluctuations, corrosive soil conditions, and harsh weather patterns that accelerate degradation in standard foundation systems. This resilience translates into reduced maintenance costs and extended operational lifespans for critical pipeline infrastructure.

Critical soil conditions and installation parameters

Successful micropile installation depends heavily on precise soil assessment and optimal ground conditions. Engineers must evaluate bearing capacity, soil density, and groundwater levels before determining the most effective installation approach for oil pipeline foundations.

Clay soils with high plasticity indices often require specialized drilling techniques and modified grout mixtures. Sandy formations provide excellent drainage but may need stabilization during installation. Rocky substrates offer superior load-bearing capacity yet demand powerful drilling equipment and carbide-tipped tools.

- Minimum bearing capacity: 150 kPa for standard pipeline loads

- Installation angle: Typically 15-30 degrees from vertical for optimal stability

- Grout strength: Minimum 28 MPa compressive strength at 28 days

- Spacing requirements: 2-3 pile diameters center-to-center distance

- Depth parameters: Minimum 5 meters into competent bearing strata

Temperature fluctuations and corrosive environments in oil and gas applications require enhanced protective measures. Proper casing selection and corrosion-resistant materials ensure long-term structural integrity in challenging subsurface conditions.

Specialized micropile systems in oil pipeline development vs traditional methods

The evolution of pipeline foundation technology has transformed how engineers approach critical oil infrastructure projects. While traditional concrete foundations remain widely used, specialized micropile systems offer distinct advantages in challenging terrain and demanding operational conditions.

Traditional foundation methods typically rely on large concrete pads or driven piles that require extensive excavation and heavy machinery access. These conventional approaches often struggle in unstable soils, environmentally sensitive areas, or locations with limited working space. The installation process can take weeks and requires significant ground preparation.

Micropile systems present a fundamentally different approach. These high-strength steel tubes penetrate problematic soil layers to reach stable bearing strata, providing superior load transfer capabilities. Installation requires minimal ground disturbance and can proceed in restricted access areas where traditional equipment cannot operate effectively.

From a cost perspective, micropiles demonstrate competitive advantages through reduced material volumes, faster installation timelines, and minimal site preparation requirements. Maintenance demands are notably lower due to the corrosion-resistant properties of modern micropile materials and their reduced exposure to surface-level environmental factors.

The adaptability factor proves crucial in oil pipeline applications. Micropile systems can accommodate varying soil conditions along extended pipeline routes without requiring design modifications, unlike traditional foundations that often need customization for each specific geological condition encountered during construction.

Economic considerations and investment planning

The economic landscape of micropile oil pipeline projects requires comprehensive financial analysis that extends beyond initial installation costs. Investment decisions in specialized infrastructure demand careful evaluation of soil conditions, project duration, and long-term operational requirements. Traditional foundation methods may appear cost-effective initially, but micropile systems often deliver superior value through reduced maintenance cycles and enhanced structural reliability.

Cost structures vary significantly based on site accessibility, drilling depth requirements, and load-bearing specifications. Remote pipeline locations typically increase transportation and mobilization expenses, while complex soil conditions necessitate specialized equipment and extended installation timeframes. However, micropile technology’s ability to handle challenging geotechnical environments often eliminates the need for extensive soil preparation or alternative foundation solutions.

Return on investment calculations must incorporate lifecycle performance metrics including resistance to ground movement, corrosion protection, and minimal maintenance requirements. The reduced environmental footprint of micropile installations can also translate to lower permitting costs and faster project approvals. Smart investment planning considers these variables alongside immediate construction expenses to optimize long-term project economics and operational efficiency.

Your technical questions answered

Navigating the complexities of micropile technology in oil pipeline projects requires specialized knowledge. Here are the most common technical questions our engineering teams encounter from project managers and contractors.

What are micropile tubes and how do they work in oil pipeline construction?

Micropile tubes are steel-reinforced deep foundation elements that transfer loads to stable soil layers. They support pipeline infrastructure by creating stable anchor points through challenging terrain and unstable soils.

What are the advantages of using micropile systems for oil pipeline projects?

Minimal site disruption and versatility in various soil conditions make micropiles ideal. They provide superior load-bearing capacity while reducing construction time and environmental impact compared to traditional methods.

How much does micropile tube installation cost for pipeline infrastructure?

Installation costs vary from $150-400 per linear foot depending on depth, soil conditions, and project complexity. Long-term value often exceeds initial investment through reduced maintenance and enhanced stability.

What soil conditions are best suited for micropile oil pipeline foundations?

Micropiles excel in challenging conditions including soft clays, loose sands, and areas with high water tables. They’re particularly effective where traditional foundations would be impractical or unstable.

How do micropile tubes compare to traditional foundation methods for pipelines?

Micropiles offer superior performance in difficult terrain with faster installation times. They require less excavation, reduce environmental disruption, and provide better long-term stability than conventional spread footings.