The UK construction industry has embraced ground protection solutions as essential infrastructure, with the sector investing £12.8 billion in equipment and materials during 2024 according to the Construction Equipment Association. Are you maximizing your project efficiency with the right ground protection system?

Understanding Different Types and Specifications

The choice of construction mat material directly impacts both performance and environmental responsibility on your project site. European hardwood represents the premium sustainable option, sourced from responsibly managed forests across Northern Europe. These mats offer exceptional durability while maintaining our commitment to environmental stewardship.

This might interest you : Strategies for uk businesses to innovate and lead their industry

Professional Build Pro Mats deliver critical benefits including reduced site damage, enhanced safety, and improved machinery mobility across challenging terrains. Tropical hardwood alternatives provide robust performance characteristics, particularly suited for demanding industrial applications. Both material types undergo rigorous quality testing to ensure consistent load-bearing capacity and weather resistance throughout their operational lifespan.

Thickness specifications play a crucial role in determining mat suitability for different projects. Standard 70mm thickness mats handle most construction equipment and temporary access requirements effectively. However, specialized applications involving heavy machinery or extended site use benefit significantly from our expertise in 85mm solutions.

Also read : Essential guide to choosing a commercial contract furniture supplier

Our 85mm thick mats bridge the gap between standard protection and specialized heavy-duty requirements. This intermediate thickness provides enhanced load distribution without the cost premium of ultra-heavy alternatives, making it ideal for projects requiring reliable performance with optimized budget considerations. The additional material depth delivers improved stability on uneven terrain while maintaining practical handling characteristics for installation teams.

Key Benefits for Construction Sites and Heavy Machinery

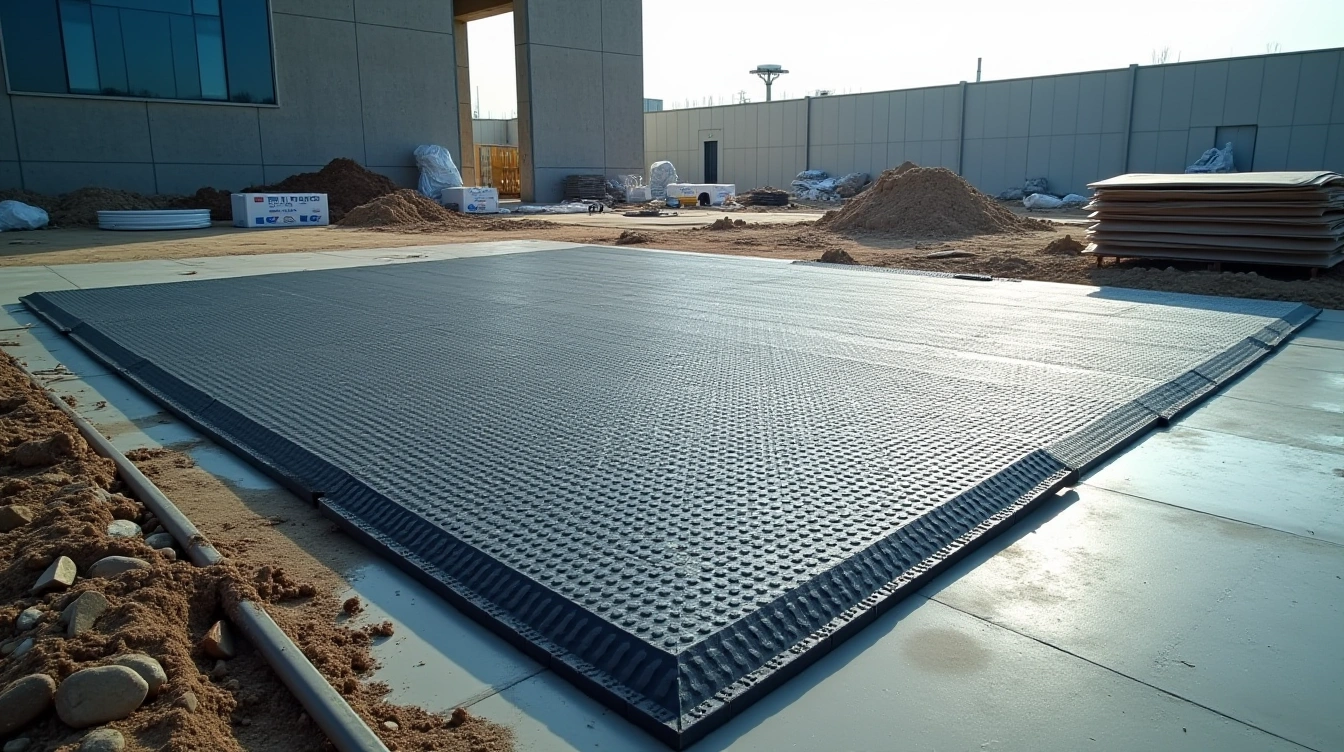

Construction ground protection mats deliver exceptional value by preserving your site’s original terrain conditions. Heavy machinery weighing several tonnes can cause irreversible damage to grass, soil, and paved surfaces. Quality mats act as a protective barrier, distributing weight evenly and preventing costly surface restoration after project completion.

The stability advantage becomes immediately apparent when equipment operates on uneven or soft ground. Professional-grade mats create a solid, level working platform that reduces machine wobble and improves operational precision. This enhanced stability translates directly into improved productivity and reduced equipment wear.

Environmental responsibility meets practical efficiency with sustainably sourced materials. Modern ground protection solutions utilise responsibly harvested hardwood from certified European and tropical sources. These premium materials offer superior durability while supporting eco-conscious construction practices that increasingly define industry standards.

The financial benefits extend far beyond initial rental or purchase costs. Avoiding expensive site remediation, turf replacement, and potential utility damage means projects stay within budget. Quality 85mm thickness mats provide the perfect balance between protection capability and cost-effectiveness, bridging the gap between standard options and delivering proven long-term value.

How to Select the Right Solution for Your Project

Choosing the appropriate ground protection solution requires careful consideration of several key factors. The wrong choice can lead to project delays, increased costs, and potential site damage.

Your project specifications will determine the most suitable mat thickness and material. Heavy machinery like excavators and cranes typically require 85mm thickness mats for optimal load distribution, while lighter equipment can work effectively with 70mm options.

- Project duration: Short-term projects may benefit from rental options, while extended use often justifies purchasing

- Ground conditions: Soft or waterlogged terrain demands thicker mats with superior load-bearing capacity

- Machinery weight: Calculate total equipment weight including attachments to ensure adequate support

- Weather exposure: Consider seasonal conditions and potential for extreme weather during project timeline

- Site accessibility: Delivery constraints may influence mat size selection and handling requirements

Professional consultation ensures you select the most cost-effective solution for your specific requirements, balancing performance with budget considerations.

Rental vs Purchase: Making the Smart Investment Decision

The decision between renting and purchasing construction mats depends largely on project duration and frequency of use. For short-term projects lasting less than six months, rental typically offers superior cost-effectiveness while eliminating storage and maintenance concerns.

Purchase becomes the smarter investment when you’re managing multiple ongoing projects or require mats for extended periods exceeding twelve months. The break-even point usually occurs around the eight-month mark, making ownership financially advantageous for established construction companies with regular ground protection needs.

Budget considerations extend beyond initial costs. Rental agreements include delivery, collection, and replacement services, providing predictable monthly expenses. Purchase requires upfront capital but offers long-term value, especially when considering the resale potential of high-quality mats after project completion.

Many suppliers now offer flexible hybrid solutions, including rent-to-own programs and seasonal rental packages. These arrangements particularly benefit contractors with fluctuating workloads, allowing them to scale their ground protection resources according to project demands without compromising on quality or availability.

Installation Best Practices and Site Setup

Proper installation of construction mats begins with thorough site assessment and preparation. Clear the work area of debris, rocks, and vegetation that could create uneven surfaces. Check for underground utilities and mark their locations before placing any mats. The ground should be relatively level, though mats can accommodate minor variations in terrain.

When laying mats, maintain consistent overlap patterns and ensure tight connections between panels. For heavy machinery applications, position mats with their strongest grain direction perpendicular to the primary traffic flow. This orientation maximizes load distribution and prevents premature wear. Leave minimal gaps between mats to prevent machinery from catching edges or creating unsafe conditions.

Optimal spacing depends on your specific equipment and site conditions. For standard construction vehicles, continuous coverage works best. When protecting landscaped areas, you can space mats strategically to allow grass and vegetation to breathe while still providing protection in high-traffic zones.

Regular maintenance extends mat lifespan significantly. Remove debris and standing water promptly, as both can accelerate wear. Inspect connections weekly during active use, and rotate mats periodically to ensure even wear patterns. Proper storage during inactive periods protects your investment and maintains performance standards.

Environmental Impact and Sustainability Considerations

The construction industry increasingly prioritises sustainable practices, and ground protection mats represent a significant step towards environmentally responsible site management. Modern construction mats are designed with recyclability in mind, utilising materials that can be repurposed multiple times throughout their service life without compromising structural integrity.

European and tropical hardwood mats offer exceptional environmental credentials when sourced from certified sustainable forests. These materials provide natural biodegradability at the end of their operational life, contrasting favourably with synthetic alternatives. FSC-certified timber ensures responsible forestry practices, supporting forest regeneration and biodiversity conservation.

The reusable nature of quality construction mats significantly reduces waste generation compared to traditional ground protection methods. A single set of professionally manufactured mats can serve multiple projects over several years, minimising the environmental footprint of individual construction activities. This approach aligns with circular economy principles, maximising resource utilisation while reducing landfill contributions.

Leading suppliers increasingly invest in carbon-neutral logistics, optimising delivery routes and utilising fuel-efficient transport methods. This commitment extends beyond the product itself, encompassing the entire supply chain to deliver genuinely sustainable ground protection solutions for environmentally conscious construction professionals.

Frequently Asked Questions About Construction Matting

Construction site managers and project coordinators often have specific questions about selecting and using ground protection mats. These solutions protect sensitive terrain while ensuring heavy machinery operates safely and efficiently.

What size construction mats do I need for my building project?

Mat size depends on your machinery weight and site conditions. Standard 8×4 feet mats suit most projects, while larger 10×5 feet options work for heavy excavators and cranes requiring maximum ground coverage.

How thick should ground protection mats be for heavy machinery?

For machinery under 30 tonnes, 70mm thickness provides adequate protection. Heavier equipment requires 85mm mats, which offer superior load distribution and prevent ground damage from concentrated weight points.

Can I rent construction mats instead of buying them?

Yes, rental options provide cost-effective solutions for temporary projects. Many UK suppliers offer flexible rental terms with next-day delivery, making it ideal for short-term construction phases.

What’s the difference between 70mm and 85mm construction mats?

The 85mm mats offer enhanced load-bearing capacity for extreme conditions. They bridge the gap between standard protection and specialized heavy-duty requirements, supporting machinery over 40 tonnes safely.

Are construction mats environmentally friendly and sustainable?

Modern mats use sustainable hardwood sources including European and tropical options. Quality suppliers ensure responsible sourcing practices, and mats can be reused multiple times across different projects.